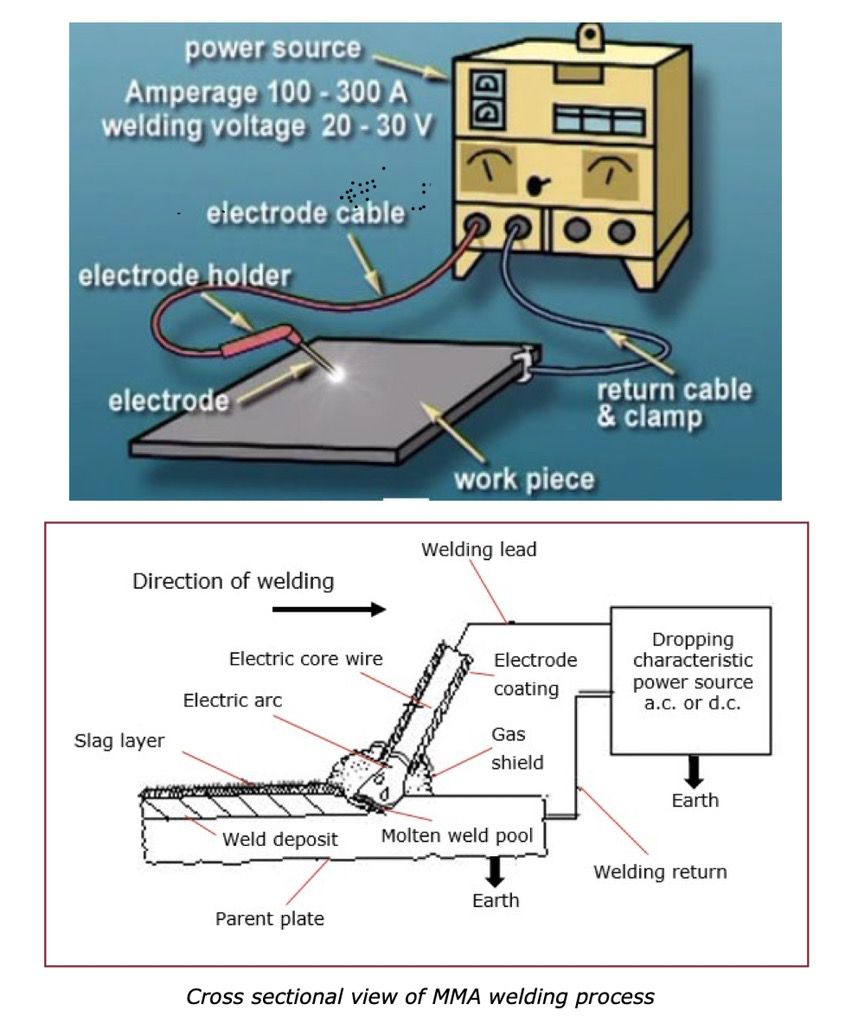

Manual Metal-Arc (MMA) Welding

Manual metal arc welding is the most versatile of the welding processes, suitable for almost all thicknesses and types of ferrous and most non- ferrous metals. Welding can be carried out in all positions relatively economically with reasonable ease of use, although the eventual weld quality is dependent mainly upon the skill of the welder. Manual metal arc welding is an arc welding process, the heat being provided by an electric arc which is itself formed between a flux coated consumable electrode and the metal being welded. The arc has an average temperature of around 6,000°C which is more than sufficient to melt the parent metal, consumable electrode and flux.

Straight polarity = rod – ve Reverse polarity = rod+ ve

Power requirements

MMA welding is carried out using either AC or DC. In the case of DC, positive (+ve) or negative (-ve) polarity may be used. The actual current form selected is dependent upon the composition of the electrode flux coating and the specified requirements of the weld. AC transformers are the most cost effective form of power source.

Power for MMA can be obtained from either transformers, transformer- rectifiers, generators or inverters.

Regardless of type, the welding plant must provide the following:

. A high Open Circuit Voltage (OCV) to initiate the arc, e.g. 65-90 volts, and a lower arc or welding voltage to maintain the arc, e.g. 20-40 volts; therefore the plant must have a drooping characteristic.

. A reasonable range of current must be available; 30-350 amps is typical. Approximately 500 amps would be the maximum capable of being handled manually.

. Arc stability. A rapid arc re-ignition (arc recovery) must be available after short circuiting without excessive current surges which can cause spatter.

. A current which remains almost constant even if, as is usual, the operator varies the arc length during welding, so that consistent electrode burn off rate and weld penetration characteristics are maintained.

Current (amperage)

The welding current, measured in amperes, controls electrode burn off rate and depth of penetration. The possible effects of having an incorrect amperage when using MMA are shown below:

Amperage too low - Poor penetration or fusion, unstable arc, irregular bead shape, slag inclusions, porosity, electrode freezes to the weld, possible stray arc strikes.

Amperage too high - Excessive penetration, burn throughs, porosity, spatter, deep craters, undercut, electrode overheats, high deposition (positional welding difficult).

Voltage

The welding potential (voltage) controls the weld pool fluidity. The possible effects of having an incorrect voltage when using MMA are shown below:

Voltage too low - Poor penetration, electrode freezes to work, possible stray arcs, fusion defects, slag inclusions, unstable arc, and irregular bead shape.

Voltage too high - Porosity, spatter, arc wander, irregular bead, slag inclusions, very fluid weld pool, positional welding difficult.

Speed of travel

The speed of travel affects heat input and therefore also affects metallurgical–and mechanical–conditions. The possible effects of having an incorrect welding speed when using MMA are shown below:

Travel speed too fast - Narrow thin bead, slag inclusions, fast cooling, undercut, poor fusion/penetration.

Travel speed too slow - Excessive deposition, cold lap, inclusions, irregular bead shape.

Current type

The current type, and more specifically its polarity, determines the heat distribution at the arc.

DC electrode positive

An electrode connected to the DC +ve pole will have two thirds of the available energy–which is mainly heat–developing in the electrode tip with the remaining one third of the energy in the parent material.

This connection produces a wide, shallow weld pool with a broad HAZ, which together slow down the rate of cooling and reduce the possibility of hydrogen entrapment and/or the development of a brittle metallurgical structure.

DC electrode negative

An electrode connected to the DC -ve pole has reversed energy distribution compared to DC +ve and therefore has one third of the energy develops at the electrode and two thirds of the energy in the parent material.

This creates a rapid development of the weld pool which is narrow, deep and fast freezing with a limited HAZ. Using this polarity with certain electrodes, may lead to hydrogen entrapment and a brittle metallurgical structure which is more susceptible to cracking during contraction or when external stresses are applied.

AC

In an AC arc the polarity is reversing 100 times per second (50 CPS*). This has the effect of equalising the heat distribution; half the heat at the electrode and half in the parent material.

The weld zone and mechanical characteristics are therefore midway between those produced with electrode DC +ve and electrode DC -ve.

*CPS = Cycles per Second

Note: 1 cycle per second = 1 Hertz (Hz).

Consumable electrodes

Three electrode types/coverings are commonly used:

- rutile

- cellulose

- basic